INTRO

This page documents my contributions to our show, where I played a key role in both the creative and practical aspects. I curated a zine that captures our group's work and creative journeys, showcasing a diverse range of talents. In addition, I was involved in designing and setting up the exhibition space, including the construction of the tables and their legs, ensuring the presentation reflected the quality of our work.

Initially, when we were told about this project, I was worried about the time frame. Once we got our heads together and we all understood the brief, it quickly came together. During the first meeting with Mark about this project, he selected some team leaders and delegated what needed to happen in the next three weeks. I was one of three who volunteered to be one of these team leaders. I was unsure of what was needed from me, as Oonah and Astrid had already taken on the first suggestions of what needed to happen. Oonah was up for the setup on the Tuesday before the show, and Astrid took control of how everything would be displayed, she made sure that we had enough of all the display units and legs we needed.

Once we had finished our first meeting with Mark, I felt as if I needed to make sure everyone (involved or not) knew what was happening and when the deadline was for everyone's individual WIP. I set out to communicate what was happening clearly to everyone, I think this is because I feel like I don't yet have a set role as a leader.

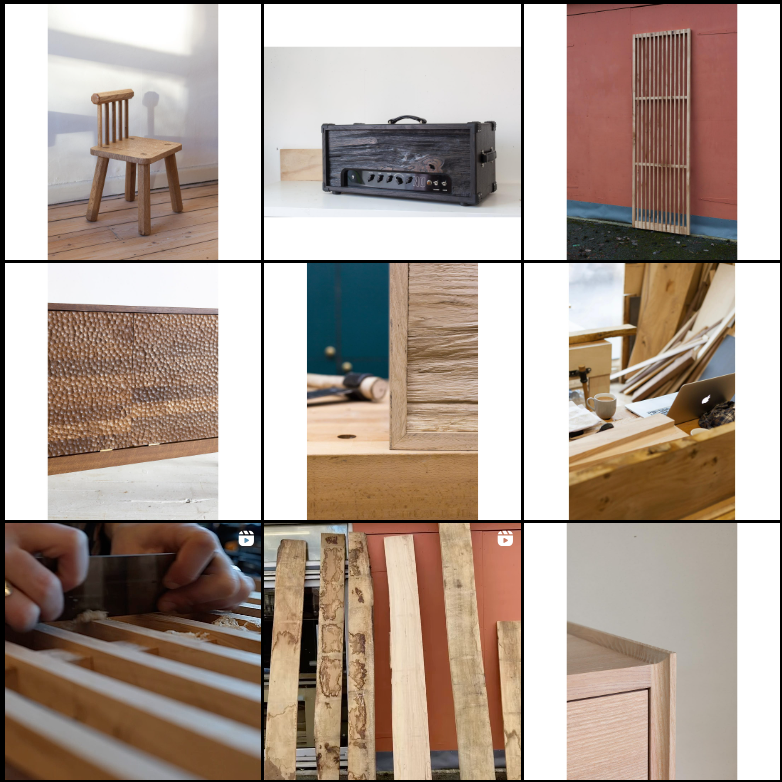

THE LEGS

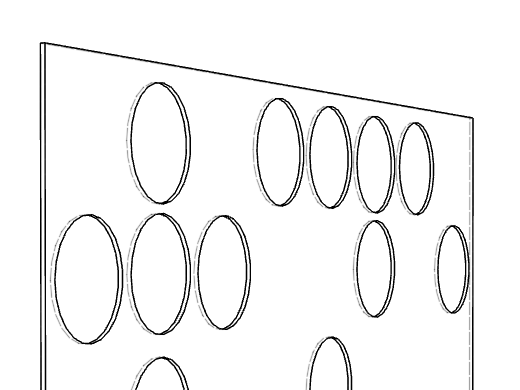

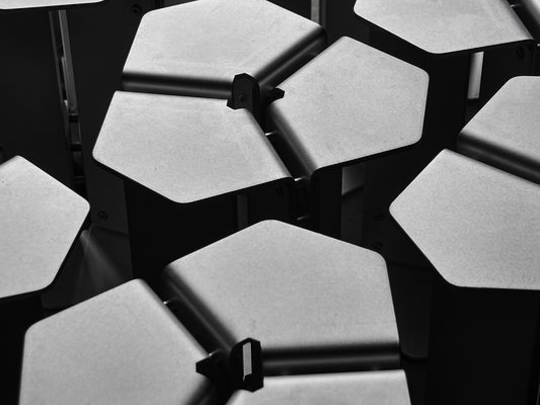

I then started designing and making legs for the tables. Astrid had quickly told everyone that they needed to make a minimum of 25 legs each to make Mark's design come true. I first didn't love the idea of Mark's design. He wanted loads of little legs and he wanted the tables to be no higher than 6 inches off the ground. I understood that he wanted our exhibition to be different from your standard display so it would stand out to those who came to visit, which is perfect as we all wanted these professionals across different industries to see our work and notice us before it came to our graduation.

I teamed up with Gregory to make the legs. As he wasn't inducted into the wood workshop, he asked me to cut some scrap wood we collected earlier that morning. When I was in the wood workshops, I cut all the planks into several (six-inch-high) pieces. I found whilst I was in the workshops, that I could cut different/isometric patterns along the edge of each piece. Once it did this, I screwed them together to make different forms and patterns on one side but sturdy enough so it was stable to hold up the boards, which had a nice depth to them. To screw the boards together, I lined them all up side by side and clamped them in the vice. I drilled a pilot hole in each of the leg designs to make sure the wood didn't split if I screwed straight into it.

Greg had the great idea to add colour to each of these legs by adding coloured electrical tape around them. The electrical tape had a really nice material property in that it would stretch and stick to the wood while leaving the contours of where the jagged edges reside.

You can see the original forms and the finished forms in the slides above this text.

THE ZINE

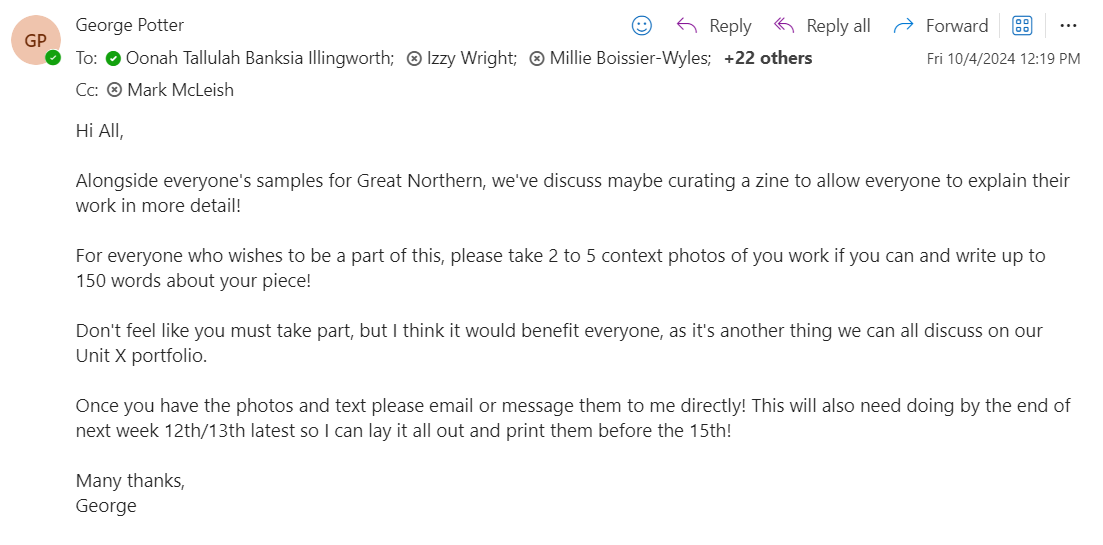

After our second meeting with Mark the week after, we explained where we were at with all the legs people had made and questioned what needed to happen next. We discussed the idea of having another platform for people to have to explain their work, whether this was through text, images, or videos! We had already been briefed by Geoff to have a process video uploaded to Instagram at this point, so we knew having a place for people to write and explain what their work is about and where their inspiration has come from was essential.

I wanted to take responsibility for this as I felt I had not done enough to share the credit with the other two leaders and everyone else helping out. I also felt I could use my level of expertise in graphic design and create a zine that displays everyone's work in a minimal professional manner.

THE PROPSAL

The first step to curating this zine was sending out an email to all my peers asking them to start thinking about what they are making and how they can summarise their practice down into 150 words. I also asked everyone to gather either context images or professional-style photos of the samples that they would be handing in. This later changed due to different ideas of what the photographs should be, and also some people wouldn't have their samples ready to photograph in the time I needed.

In this email, I asked everyone to get the words and images to me as and when they could. Instead of setting a deadline and sticking to it, I gave a ballpark time frame of any time the weekend before the show. In doing this, I learnt that giving people a set time gets things done quicker, and you'll hear from everybody when you need it.

During our second meeting with Mark, he said to make sure everyone gets it to you by Friday at 9 pm so I have time to curate the zine over the weekend. Bethan kindly sent out another reminder to everyone about the samples and said that my new deadline was Friday. I also made sure to tell everyone I saw about this so everyone understood. In the end, some people were having difficulty balancing their time either because they had to make new or different samples due to failed attempts or due to work. I understood that some people were confused, as I was initially unclear about when I wanted this work, so I was very lenient with people sending me the content for their pages. I also wanted everyone to be included in this, as it was a big opportunity to show and explain your work to professionals in a similar field!

THE PAPER

As the idea of the zine was only properly spoken about in our second meeting with Mark, I only had a short time frame to organise and get everything together so it would be ready in time for the show. On Thursday, the 10th, I made sure I had spoken to the Make More Store about the paper alongside digital media for the printing. I was going back and forth between these departments to make sure I was ordering the right things and not wasting the budget.

Digital media helped me work out how much paper we would need to print 100 of these Zines with each, being 60 pages of A5. We worked out that it would be printed on A4 and folded in half to make the A5 size booklet, and each page would be printed double-sided so there wouldn't be blank pages throughout the document. This took us down to 15 sheets of A4 paper per zine!

This meant creating 100 zines at 15 pages per zine would equal 1500 pages.

This seemed like a lot, but when I got the quote for the price of the paper, it didn't seem too bad.

I went to order this paper from the Make More Store after working out how much of it we needed. I understood it was a big order, so I was glad I did it before the weekend instead of assuming they would have it in stock on Monday morning. We spoke about the GSM of the paper I needed; this just means how thick we wanted the paper for the zine. It couldn't be too thick, as otherwise it wouldn't be able to fold but anything too thin would feel cheap and wouldn't represent us all in a good fashion. We ended up going with 100 gsm cartridge paper as it had a thick enough quality to look professional but was thin enough to fold 15 sheets together.

I came back in on Monday morning at 9 o'clock. This is when I was told the paper was going to be ready. I had planned my day on Monday to collect the paper and start printing before our seminar with Geoff. This all got pushed back when I went to collect the paper and was told I had given the wrong quote for the paper at the end of the previous week. I was told for the 1500 sheets of A4 it would be £9.40. I questioned this at the time as I thought it was cheap, but upon collection of the paper, I was told it was going to cost £78.20. This came as a shock, as that's almost £70 more than the original figure I was told about.

I had to go and speak to whoever was around at this time to see if they could pay for this using the budget code. I found and spoke to CJ about this "hiccup" and explained that the paper needed to be paid for in one transaction as they had changed the limits of how much you can buy with a budget code. The limit was £30 maximum, which exceeds 2 separate payments. I'm not too sure how we got around this, but I was very thankful to those at the Make More store who made this "one-off" order possible. It had gotten to 10:30 when we had our seminar with Geoff, but after this, I collected the paper and headed straight to digital media to start printing, as I wanted to get all these zines printed and binded that day.

PRINTING

On the 10th, when I spoke with a member of the Digital Media team, I was told that someone should be around to help me print between 10:30 and 11:00 on Monday. As my schedule had already been pushed back, I had missed one of the supervisors. I still went to see who was around and spoke to someone coving. They couldn't help me much, as they didn't know much about the scale of what I needed printing.

They then directed me to Print City. After sending them an email asking if I could print on all of these pages today, I got a very confusing reply suggesting that I'm speaking with the wrong department as Print City runs the 3D printing across the uni. They then directed me to the printing services. This was in a building not far from print city but I was just emailing to get a quote and see if they could work in my time frame.

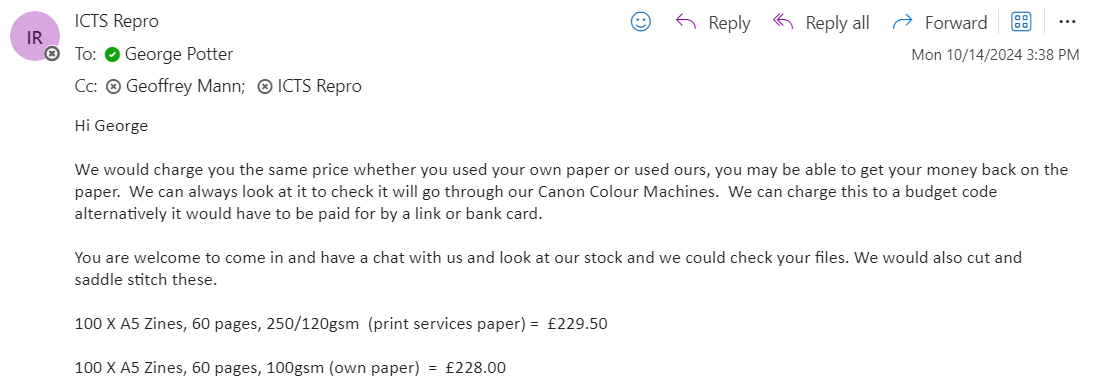

Later that day, I finally heard back from the printing service with a quote. Firstly, they said they could provide the paper and bind the zines together. As I had already spent almost £80 out of the budget, I thought it would be best if we used it, so I asked him to give me a quote for both the paper I could provide and his original quote. The quotes were a big shock to the system. I knew it might be expensive, but I wasn't ready for how much it cost. The printing was going to cost a total of £228; this was with using out paper. The quote for them to print and provide paper was only £1.50 extra at £229.50. At this point, I was concerned, as I felt as if I had wasted the budget on buying the paper first before seeing how much it would cost to print.

After speaking with Geoff about this ungodly amount of money for these zines, he also did not know what to do as the price was very steep. Geoff said I would have to wait until tomorrow (Tuesday 15th) until he had been given the go-ahead to spend all this money for this. At this point, I was unsure of what was happening, so I just waited to hear back the next morning.

Upon the arrival on Tuesday, Geoff said that we wouldn't be spending that much on printing, as the budget had to also cover the costs of the textile students who we were sharing the exhibition space with. This was a bit of a letdown, as I initially didn't think we would be printing any. Geoff suggested that we have the zine accessible to people online, which I thought was great; however, I still wanted people to be able to refer back to a physical copy of the zine as they were looking at our work. I said to Geoff I would happily pay to print a handful of zines as I put a lot of effort into putting it all together. We discussed that it would definitely be available to people online and that we would still be printing some, just not as many as 100. I was so relieved about this, as I really wanted to be able to share this with everyone on Thursday night.

Binding

Once we had the pages for 20 zines printed, it was time for the next steps. Fortunately, the pages print in the order they're meant to be, so we didn't have to reorganise all the pages. We just had to separate and fold all 15 sheets together. I started this by making sure all the pages were aligned before creating a light fold down the centre of the paper. I then boxed up all the slightly folded zines and headed down to the binding workshop. I set myself up on the stapling machine, which I was familiar with as I did a few tests on Monday. Here is a video of the process in this workshop.

Once all the pages were binded they needed trimming so all the pages were even at the edge. I also tested this on Monday so I could jump straight in. This process can also be seen at the end of the video above.

I complied the videos into one edit for this workshop so you can see my workflow clearly.

THE SHOW

Despite the stressful start to the week of the show, it was smooth sailing for the rest of the week after the setup was completed. I used this week to update my portfolios and also create social media posts to advertise the event. On Thursday night, we all met for the opening of the event. This event was on from 6 to 9. I was overwhelmed by the size of the show and our exhibition space; this was the first time I had seen the setup. The idea of the display never jumped out at me from the early ideas; however, I liked how the scale of the display shelves matched the scale of our samples. This did a good job of making all our work look cohesive as a craft course. It shows what this industry is about and how we come together across such different practices to celebrate one another.

As the show ran from Thursday night till Sunday night, we all had rotating shifts, which were assigned to us by Kate, who gathered everyone's accessibility for that weekend. I was assigned the first opening shift on Friday morning; it was nice to see all the friendly faces from the night before. I found that on Thursday night I was too overwhelmed with how busy it was I didn't get to speak to anyone I wanted to.

On Friday morning, while I was at our exhibition speaking to all the visitors about everyone's work, I had a great conversation with one of the event organisers, Daisy Fulton. She was very impressed by the zine I had made for everyone and asked if I had previous experience in graphic design. I showed her some of the previous graphics I had done and said to reach out if she ever needed me to do anything for any of her exhibitions, etc. About 6 weeks after the show, I received a message from Daisy asking if I had any free time to make a poster for her upcoming exhibition. Unfortunately, she needed it in a timeframe that didn't work for me because of the workload I already had. She completely understood, as she had recently graduated and knew how much work you have in your final year. I told her not to hesitate to reach out again next time she needs any graphics or designs, and hopefully, the timing will work out better in the future.

Later on Friday, once the others had arrived and my morning shift was over, I had complete freedom to roam around the show again and build up the nerve to speak to other practitioners. I first spoke with Doug Nicholson at External Combustion. He is a craftsman based in Derbyshire who creates amazing sculptures, primarily of animals (birds in particular) I had a good conversation with Doug about how he had gotten to where he is now, and it was interesting to hear how long he had been crafting with metal. He was saying he spent the past 35 years doing TIG welding and has now moved to MIG welding, which he said was a difficult process to learn as he was so used to TIG. The attention to detail in Doug's sculptures was inspiring, and it was nice to see a fellow metal craftsmen at the show, as there weren't many.

I then continued walking around, hoping to find Nick from Studio Critical. He is someone I knew of before the show and have followed for a while. I had seen on his Instagram that he was going to be the show, and I didn't see him or his stand on the opening night. Before getting around to him I saw Aidan Donivans stand, He is another practitioner who was in my research from last year when we were looking at writing a proposal for GNCCF. I went to speak with him about his work, which was funny as one of his modular systems was called KIT. We made a joke and laughed about this, as I had also used that name last year without knowing he had done the same. He said he was for a different reason though, as a client's son, who he made this piece, which had these modular capabilities, was called Kit.

We then went on to speak about how he's done so well throughout his career and made a living off crafting beautiful bespoke furniture. He said that when he was at my stage in his career, he found a mentor in the industry who showed him the ropes. He then went on to offer to mentor me and teach me the skills he had learned on his journey so far. This was so nice of him to be so welcoming and kind, as it was the first time I had met him, but I think he liked how interested I was. We exchanged details, and he said to reach out anytime I ever feel stuck or lost.

The attention to detail in Adian's work is remarkable. However, I lack the skills and interest in woodworking! Its not something I'm totally against; I just have such a strong love for working with metal, and those are the skills I've been learning for the past 2 years.

I then found Nick. We had a great conversation similar to the one I had with Aidan. These were both lovely to chat with and have really been great role models.