For this section of my portfolio, I have split it into 2 sections. The first is the pricing of my object when hand-crafting each component, and the other is the further development of my idea to take it into manufacturing where I have real quotes from steel manufacturers for the machine-cut components. This is because I wanted to explore further how much this product would cost me to recreate in both circumstances.

Pricing Workshop 1

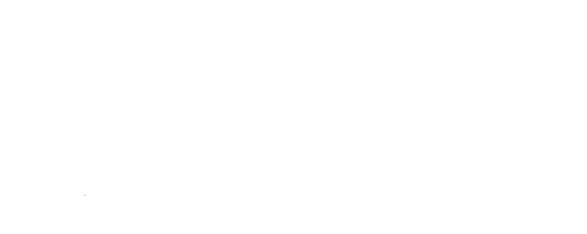

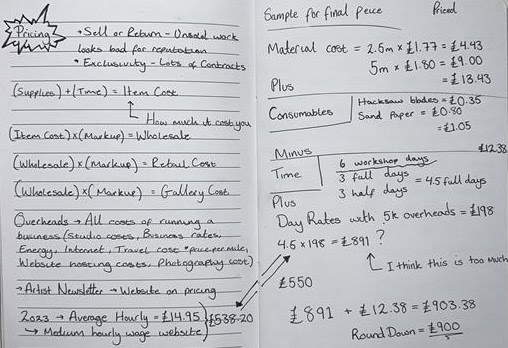

These images are from my sketchbook when we did the first pricing session for uc2 with Rachel. This was confusing as I didnt have a final piece to price so we were told to price the samples we had made so far. I don't think these were very accurate as I wouldn't charge £800 for my sampled chair. However, from the further workshops we did on pricing, I can see that we missed out on alot of factors to justify a final price.

Hand-Made Pricing

Material Cost (University)

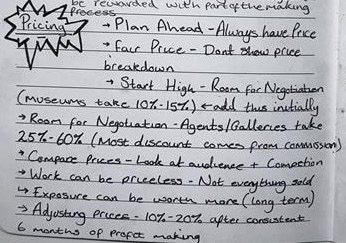

After I had finished making my final piece I added up all the costs and overheads that I spent on making this piece. As you can see the pricing in materials for this piece cost me £86.51 This doesn't count into the fact that other prices including travel, sustenance, etc. this is purely for how much I spent on materials in uni making this prototype/final piece. This included a list of things that I included as part of my hand-in, like the ratchet straps and grubs screws which I sourced from outside of uni.

Parts of my design that I included in the pricing, like the ratchet straps, weren't a necessary component in the design. I showed these to demonstrate an array of options for seating if I were to make this into a product. When I do decide to develop this idea there will be more and more options available

Now that I had figured out how much everything cost me in uni, I looked at what machinery I used to make it. I didn't use a mass amount of Machines but I listed them at the bottom of this page in my sketchbook. The reason I did this was so I could go onto the next step of finding a workshop to rent after uni which accommodates all of these machines.

Finding a Workshop

I did some more research and found Leigh Works. This seemed like the best option I had come across so i figured out all the pricing that comes along with renting a workshop space like this.

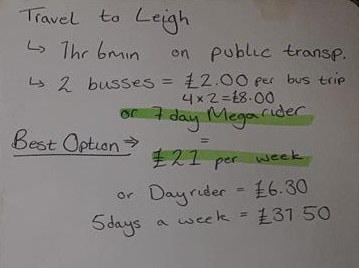

Travel Cost

Once I had found the best and cheapest available workshop to make this product at I figured out my travel cost. To do this I looked at the quickest way I would get there from my flat and as there were no trains to Leigh the best options were the bus or tram. The journey Google Maps suggested was 2 busses and said it would take 1hr and 9 mins so I looked at the cheapest options to get if I was to work and go into these workshops 5 days per week. The workings are on the image below and it shows that getting a weekly day pass would be the best option however, if I knew I would be there for longevity I would possibly choose an annual rider through stage coach which may work out even cheaper.

Material Cost (Outside of Uni)

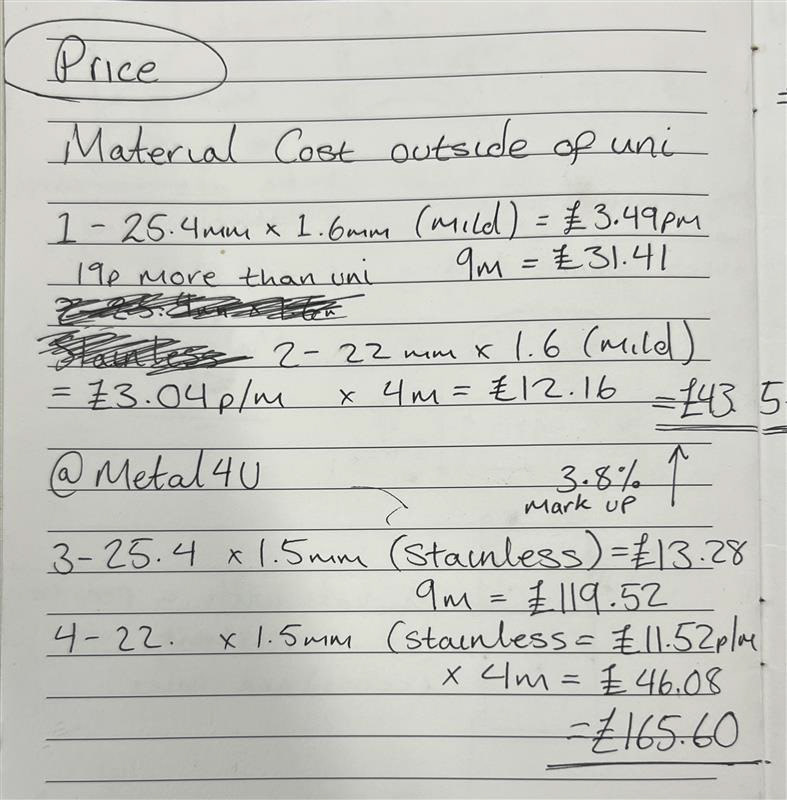

I then looked at the material cost outside of uni. The best website I found was Metals4u which catered to the materials I needed. Below are the Price Differences between Mild Steel and Stainless Steel. I am comparing the prices of both of these materials because it was a consideration when designing my piece. I knew for this project I would use mild steel, this was primarily due to the university only stocking this and because the price of stainless steel is significantly more expensive. The link can be found here to where I got these quotes from.

When ordering materials there are a range of factors to consider, you first need to know exactly what you need and how much of it you will need. This is a big part of the design stage and must be planned out before purchasing any materials.

As I know how many materials I have used it has been a bit easier to figure out an overall price. I have used 9 meters of 25.4mm x 1.5mm tubing and 4 meters of 22mm x 1.5mm tubing so I knew this would be the material used per chair.

This page can be a bit confusing to understand so I will break it down for you. I used the website Metals4U, this was the best option I found as the material list was huge and the selections of different sizes, finishes, metals, and thicknesses were perfect for what I needed.

The short story is that I needed 9 meters of (25.4mm) tube and 4 meters of (22mm) tube with both the same thickness of (1.5mm)

9m (mild) = £31.41

4m (mild) = £12.16

Overall Cost of Mild Steel = £43.57

9m (stainless) = £119.52

4m (stainless) = £46.08

Overall Cost of Stainless Steel = £165.60

As you can see stainless steel is significantly more expensive and would require alot more care I would have to be more cautious to not scratch or drop these tubes as it would damage the finish of the steel. This doesn't just apply to the more expensive option as on this website you can also pay more and request the tubing to come with different finishes. This could save time in the making process however it would also mean I would have to handle the components with alot more care which could lead to some components being scraped. I am sure if I was hand-making multiple of these at a time, I would get into a good rhythm of curating each component with care.

I then looked at all the overheads that I believed would cover everything for me to make this product again after university. I estimated alot of the costs as I'm not sure how much some of the aspects of this spreadsheet would total up to and it's all dependent on how many of them I can make per month. I then figured out how many numbers of weeks I'd choose to work per year and how many hours I would work per week. These may seem high however I believe if I were to put in the hours into creating a brand/business it would reward you in the long term.

This left me with an hourly rate of £34.98

I then divided this by 60 to see my rate per minute which is £0.58

I then decided how long it would take me to make this chair again given I know the process of each stage. I estimated around 600 minutes in the workshop (equivalent to 10 hours)

I then Multiplied my rate per minute (£0.58) by how many minutes were taken (600) this left me with £349.80

The next stage is dependent on the material used. I took the the current price of my piece and added the material cost but as I had 2 variables I had 2 different price outcomes.

For the mild steel chair, It would be £349.80 + £43.57 = £393.37

For the Stainless Steel chair, It would be £349.80 + £165.60 = £515.40

I then have to add the markup which I multiply the current price by 2 because if my work is shown and sold in a gallery they take 50% of the outcome. I am not sure if this applies to me as I have chosen GNCCF and they don't take a commission for any sales, They just take an exhibition fee at the start.

So the final retail price for my chair would be:

£789.74 = Mild Steel Retail Price

£1,030.80 = Stainless Steel Retail Price

Manufactured Pricing

For this section I haven't found an overall price for my piece, I've just looked at quotes from factories to get the exact price for them to manufacture my components with perfect precision. I've been in contact with Geomiq, They are a steel manufacturing company who were based in London but now work with thousands of companies all across the world. They aim to help to world of engineering by creating "parts at the best possible price".

I first made a 3D model of each component with perfectly accurate measurements to meet my requirements. I then made these models into individual bodies so I then could export them to the appropriate file (STEP. file) which i could then upload onto the website and select through the vast options of metals, finishes, and sizes.

I have asked for these components on this quote to be CNC cut as I believe it is the best option for what I want, I am still not entirely sure if this would be the best way but the services the offer at Geomiq were CNC, Injection Molding, and 3D Printing.

I received the quote from this company to manufacture the exact amount of components for my chair. This was very expensive and would cost £1497.76 for the material cost. This doesn't cover my hourly rate, Markup and other overheads.

I also looked at bulk buying these components looking at how much it would cost to make 100 chairs and 1000 chairs. I received the quote for the components to make 100 chairs. This brought the unit cost down significantly to £5.16 per straight part and £21.08 per corner part. This looks alot more profitable however it requires alot more of an investment as even though the unit cost is going down, the sub total for the order rises dramatically.

Overall the material cost for these 100 chairs to be mass manufactured would cost me £37,680. Again, this doesn't include my hourly rate and other overheads like the actual fabric seating parts etc.

This means in total it would cost £376.80 in material costs per chair.

If I were to calculate this using the same equations and hourly rate I gave myself for the crafted price I would add £349.80 to that current cost of £376.80

= £726.60

And then if I were to give it the same mark-up and multiply this current number by 2

The total retail price of £1,453.20

Using this as a retail price, If i sold all 100 chairs the gross income would be £145,320

This means the total net profit would be £107,640

If I were to manufacture and sell 1000 chairs the unit cost would go down meaning it would be cheaper per chair in material cost. This would obviously be a higher sub total however if I were to take this price and sell 1000 chairs at £1453.20 It would total a gross income of £1,453,200

Crazy!