As my practice evolves, so does my approach to research and inspiration. In this section, I will explore a range of companies and artists whose work influences my design process. Unlike my previous research, which focused primarily on traditional handcraft artisans, my current direction is more aligned with design for manufacture—considering how materials, processes, and industrial production techniques shape contemporary design.

By examining both established companies and innovative designers, I aim to gain insight into how creative ideas are transformed into functional, manufacturable products. This research will not only inform my technical understanding but also inspire me to bridge the gap between artistic vision and large-scale production. Through this, I hope to refine my own design language and develop work that is both aesthetically compelling and practical in a commercial context.

DESIGNERS

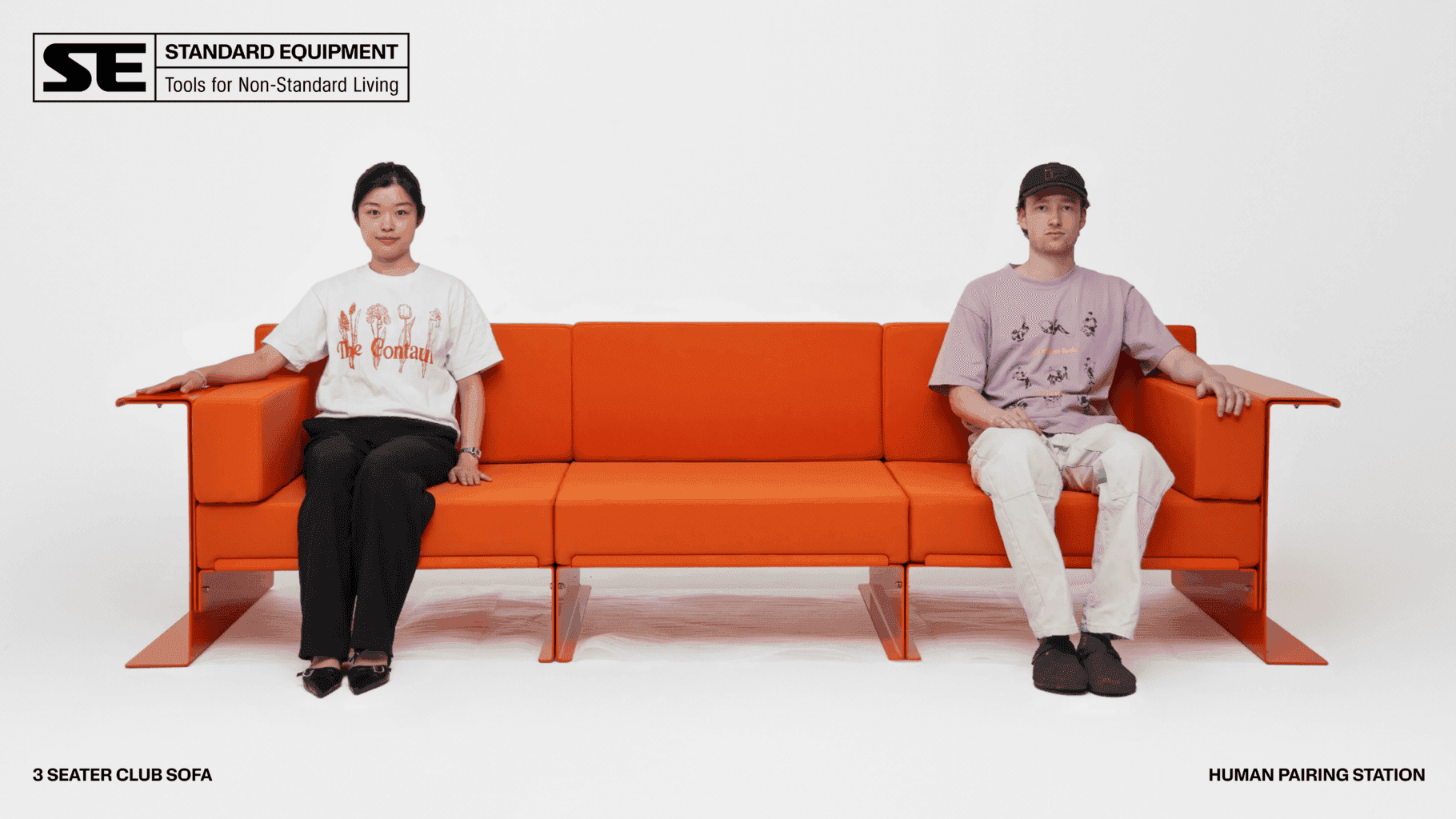

Standard Equipment is a Toronto-based design studio founded by Josh Gadomski, specializing in homeware and furniture that embody a playful and functional aesthetic. Drawing inspiration from Postmodernism and industrial design, Gadomski creates pieces that are both geometric and joyful, aiming to infuse daily-use objects with a sense of fun. This philosophy resonates with my own approach, as I focus on creating modular furniture that maintains a strong visual identity while allowing for adaptable and versatile configurations.

The studio predominantly utilizes sheet metal, especially aluminum, in its creations. This choice stems from Gadomski's appreciation for the material's versatility and sustainability, as aluminum is infinitely recyclable. Similarly, aluminum is central to my own work, not just for its durability and sustainability but also for the way it allows me to maintain a cohesive aesthetic across multiple furniture pieces. His journey into furniture design began with a project that combined sheet metal and wood, sparking a lasting interest in metal craftsmanship.

Standard Equipment emphasizes sustainability by adopting a made-to-order production approach. This method ensures minimal waste and reduces environmental impact, aligning with the studio's commitment to responsible design practices. By producing items only upon request, the studio avoids surplus inventory and promotes longevity in its products. While my production approach may differ, I also value efficiency in design, ensuring that my modular framework maximizes material use while minimizing unnecessary waste.

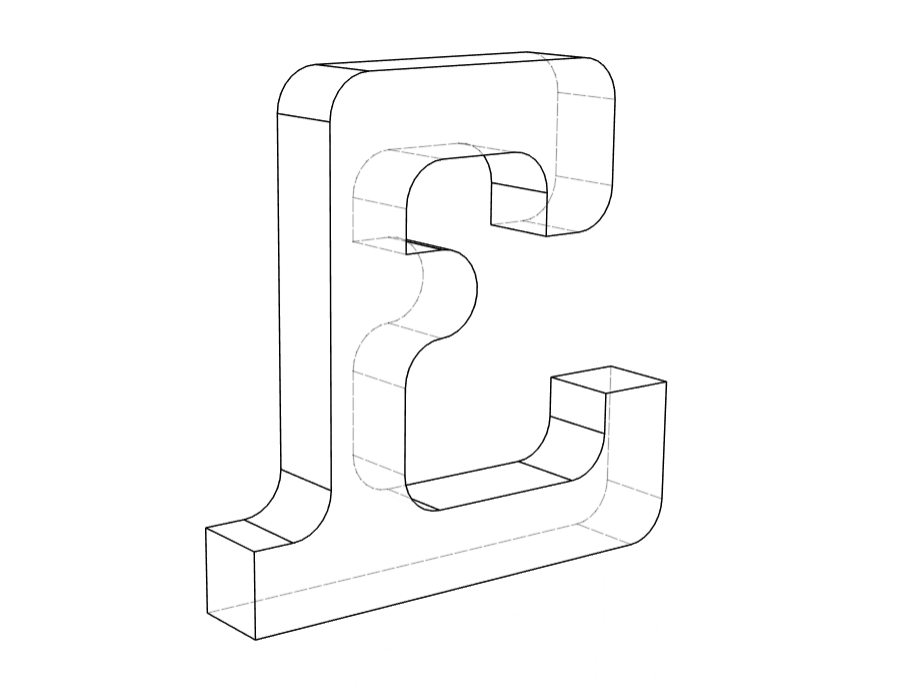

The design process at Standard Equipment begins with simple sketches, which are then developed into detailed CAD models and rendered with digital materials before manufacturing. This meticulous approach allows for experimentation and refinement, resulting in designs that are both innovative and practical. Much like this process, my own workflow moves from conceptual sketches to digital modeling, where I refine the connections between my standard component and the additional modular elements that define my furniture system.

Standard Equipment maintains a strong visual and material cohesion across its entire product range by using the same material thickness and hardware, regardless of function or scale. This thoughtful consistency creates an intriguing optical effect—smaller objects appear bold and chunky, while larger pieces take on a refined, almost lightweight elegance. This approach not only reinforces the studio’s distinct design language but also ensures a seamless aesthetic throughout their collection, making every piece feel like part of a unified, well-considered system.

From the products to the branding of standard equipment, it remains one of my favourite design companies, which heavily inspires me to create more and bring these ideas to a business of my own.

JAKUB KUBICA

Jakub Kubica is a Berlin-based multidisciplinary artist and designer, originally from Slovakia, whose work spans minimalist furniture, functional design objects, and futuristic artworks. His creations often blend natural materials, such as stone, with industrial elements like metal, reflecting a harmonious balance between organic forms and modern design.

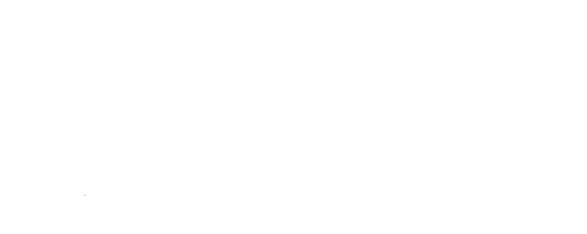

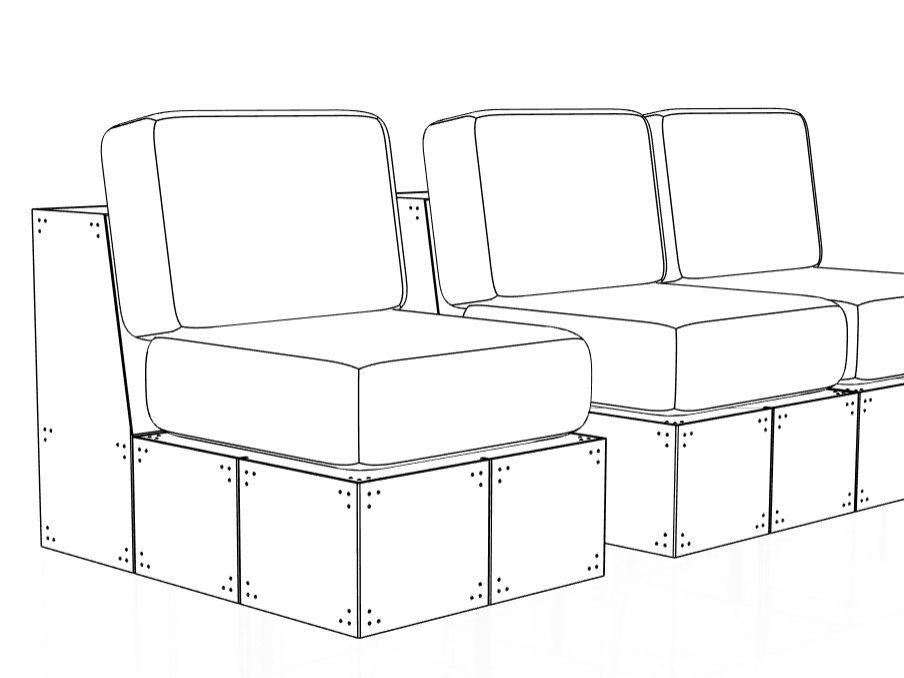

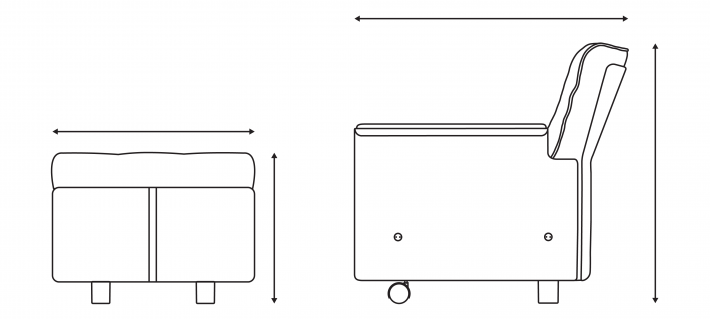

Drone Modular Sofa Chair

One of Kubica's notable designs is the "Drone Modular Sofa Chair," introduced in 2024. This piece features a minimalist aesthetic with a metal skeleton, waxed with natural bee wax and hand-polished to protect the surface from fingerprints and smudges. The seating is upholstered in vegetable-tanned leather from Tuscany, Italy, offering a timeless look that ages beautifully. The modular nature of the chair allows for various configurations, such as combining multiple units to create a double-seater sofa, providing both versatility and comfort without compromising its sleek design.

Kubica's approach to design reflects his broader artistic vision, which seeks to rediscover the known and foster a conversation about nature and human interaction with it. His work invites users to engage with their environment thoughtfully, blending functionality with aesthetic appeal.

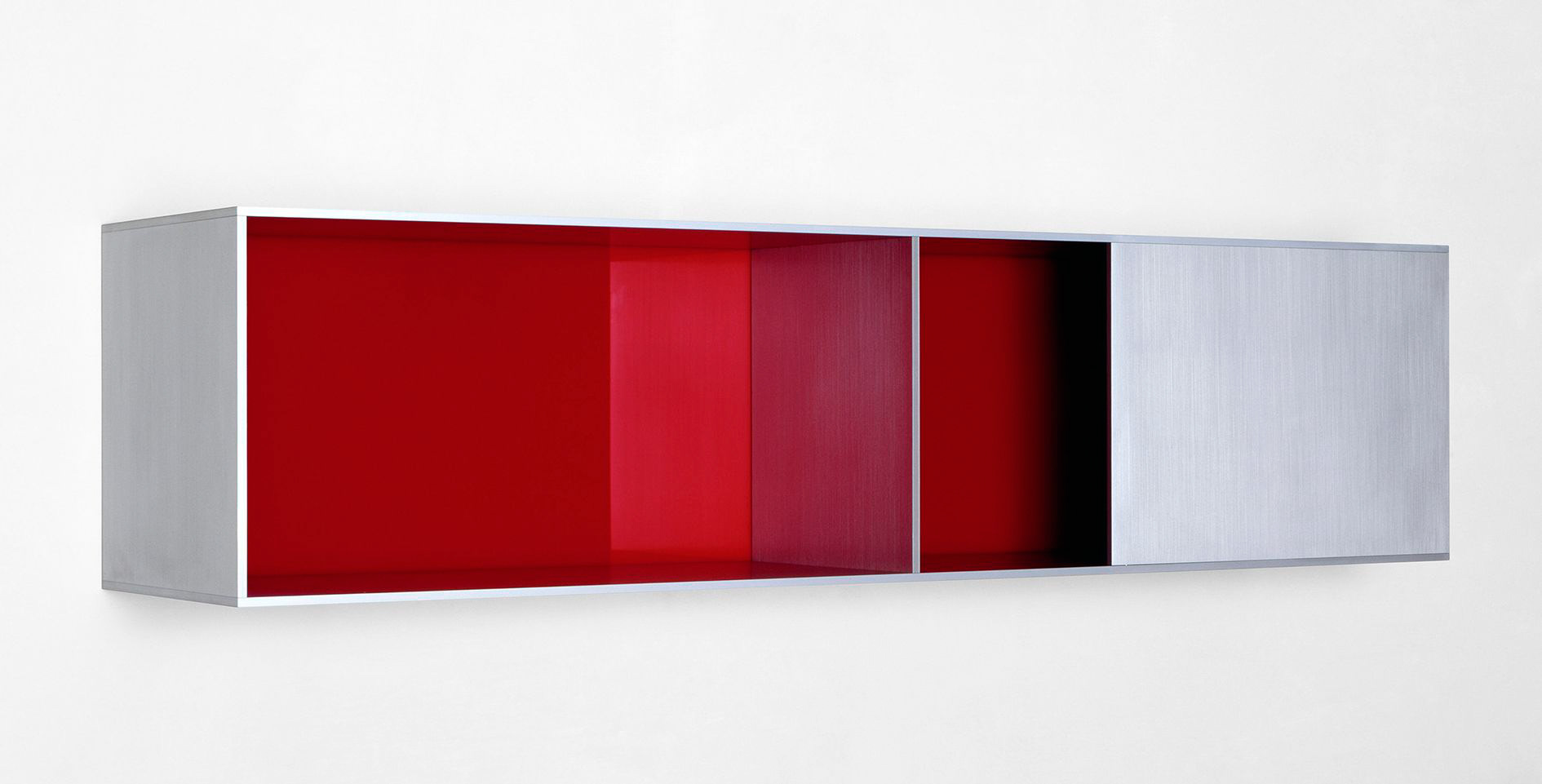

DONALD JUDD

Donald Judd (1928–1994) was an American artist and key figure in the Minimalist movement, though he personally rejected the label. He is best known for his geometric, industrially fabricated sculptures and furniture designs, which emphasize space, materiality, and form.

100 Untitled Works in Mill Aluminum is one of his most significant large-scale installations. It consists of 100 rectangular aluminum boxes, each measuring 41 x 51 x 72 inches, housed in two former artillery sheds at the Chinati Foundation in Marfa, Texas.

I really connect with Donald Judd’s philosophy, especially his rejection of hierarchy, focal points, or the need for a narrative in art. His 100 Untitled Works in Mill Aluminum is a perfect example of that—there’s no singular meaning imposed on it, no forced interpretation. It just is—the form, the material, the space, all existing for their own sake.

That approach really reflects back on my own work. I don’t always want everything I create to have to carry some deep meaning or symbolic weight. Sometimes, a piece is just about the material, the shape, the way it interacts with its surroundings. I appreciate how Judd stripped things down to their essence, letting the work stand on its own without needing justification. There’s something freeing in that—just making something because it feels right, because it exists in a way that resonates, without having to explain why.

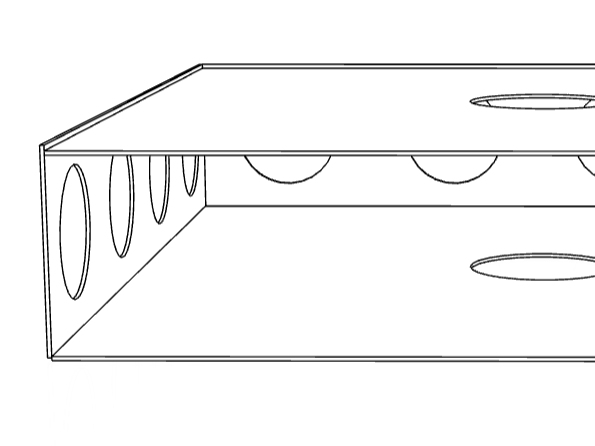

LIGHTENING HOLES AND JEAN PROUVE

At the start of this semester, I had taken an interest in lightening holes. Moreso the design aesthetic of them rather than their intended function. Essentially, Lightening holes are an engineering design choice to reduce weight from high-performing automotive vehicles and planes. This was to increase speed by decreasing the weight.

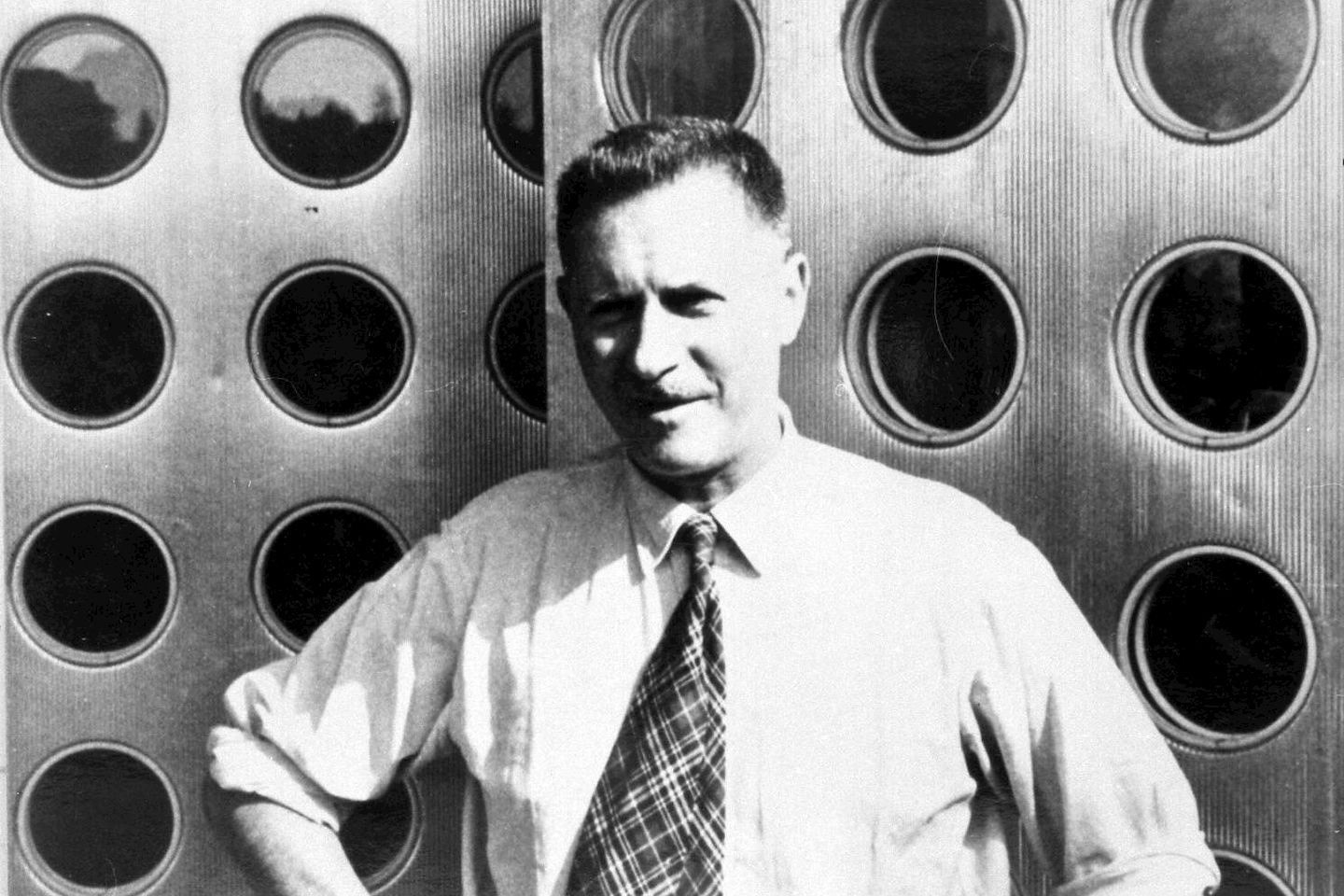

Jean Prouve

Jean Prouvé was heavily influenced by aeronautical and automotive engineering, which often incorporated lightening holes—circular or oval cutouts in metal surfaces designed to reduce weight while maintaining structural integrity. He adapted this engineering principle into his furniture and architecture, not just for efficiency but as a distinctive design language.

VITSEO

I was initially apprehensive about going on this trip, mainly due to the cost of the trains; however, when Claire messaged me on Sunday night and told me there was room on the coach, I was buzzing.

Visiting the Vitsœ factory in Leamington Spa was an eye-opening experience. For a factory, it had an incredibly calm and relaxed atmosphere, which was surprising. The space was beautifully designed, with north-facing roof lights that reflected off the slanted ceiling, preventing direct sunlight for most of the year. This created a soft, natural light that closely resembles the lighting conditions found in homes—where their furniture is ultimately used. Unlike typical industrial spaces that rely on bright artificial lights, Vitsœ deliberately avoids them, as they highlight textures in an unrealistic way.

The entire factory had a Scandinavian feel, emphasizing simplicity, functionality, and modularity—values that align perfectly with Vitsœ’s ethos. Their philosophy, “living better with less that lasts longer,” is evident in every aspect of their design and operations. Interestingly, they avoid using the term "sustainable" because it has become too broad and often misused. Instead, they focus on real, long-term responsibility. One example is their approach to materials—while some criticize leather for coming from cows, Vitsœ recognizes that it's a byproduct of the meat industry and lasts significantly longer than some newer materials, like algae-based alternatives that degrade within two years and end up in landfill.

Another standout aspect of the factory is its flat hierarchy. Unlike traditional workplaces where management has separate offices, at Vitsœ, everyone works on the same level. The warehouse team sits right next to the sales and marketing teams, reinforcing their belief in equality and collaboration.

The factory itself is a perfect example of forward-thinking design. It is completely modular, designed with longevity in mind. Features like flooring with built-in gutters allow for easy installation of future technology without major disruptions. The building can even be disassembled and relocated if needed, reducing waste and unnecessary rebuilding. Inside, office spaces can be easily reconfigured by adding glass partition walls that clip into place, making the space as adaptable as the furniture they create.

Overall, the Vitsœ factory was an inspiring place that truly embodied the brand’s commitment to thoughtful, lasting design. It wasn’t just a place of production—it was a living example of their core philosophy.

620 CHAIR

An Insight into Designing a Modular Sofa:

During our factory tour, Daniel guided us through the meticulous process of designing and manufacturing a modular sofa. He explained each stage in detail, starting with the wooden frame that forms the base. Next, he showed us the set of metal springs embedded in the seat, which provide support.

Daniel then introduced us to an innovative material the company has been using over the past decade—coconut husk. This natural fiber is layered over the metal springs, adding a firm yet cushioning feel to the seat. Once this layer is in place, multiple layers of cotton and various fabrics are applied, leading up to the final upholstery.

This careful construction process ensures both durability and comfort, showcasing the thoughtful craftsmanship behind each modular sofa.

COPENHAGEN

Copenhagen is a dream destination for design lovers, and my recent trip proved just that. The city is filled with beautifully curated spaces, thoughtful architecture, and a deep appreciation for both classic and contemporary design. One of the highlights of my visit was the Design Museum Denmark, an absolute must-see for anyone interested in the evolution of design through the 20th century.

Walking through the museum, I was captivated by how each era showcased its own unique approach to form, function, and materials. From the early modernist movements to the sleek, minimalist styles of later decades, the exhibits perfectly illustrated the progression of design thinking.

One of the most impressive sections of the museum was the Hall of Chairs—a stunning display of some of the most iconic seating designs in history. Seeing the Barcelona Chair by Ludwig Mies van der Rohe in person was incredible; its sleek leather and steel combination embody the sophistication of modernist design. Equally breathtaking was the Tulip Chair, designed by Eero Saarinen, which stood out with its futuristic, sculptural elegance. The collection highlighted the craftsmanship, innovation, and artistic vision that went into designing everyday objects like chairs, transforming them into timeless pieces of functional art.

DANSK MADE FOR ROOMS

Visiting Dansk Made for Rooms was like stepping into a carefully considered interior, where every piece felt intentional. The store featured a mix of larger furniture pieces—beautifully crafted tables, chairs, and shelving—alongside smaller decorative and functional objects like ceramics, lighting, and sculptural accessories. The selection highlighted quality materials, clean lines, and a timeless aesthetic, staying true to Danish design principles.

What stood out the most was the thoughtful curation. The store’s owner had a keen eye for selecting pieces that worked seamlessly together, creating a space that was both inviting and inspiring. Every item felt like it had been chosen not just for its style but for its quality and craftsmanship. It was the kind of store where you could easily imagine taking home almost everything, knowing it would effortlessly fit into any well-designed space.

Rather than feeling like a typical retail shop, Dansk Made for Rooms had the atmosphere of a beautifully styled home, making it easy to appreciate how each piece could work in a real setting. It was a perfect example of how good design isn’t just about individual objects but about how they come together to create a cohesive and functional space.

These are some stainless steel cups we picked up. I wish we could've brought more, but due to the price of everything and the size of the luggage we had, it wasn't possible. A definite must-go if you visit Copenhagen.

HAY

We also visited the HAY House which was a great experience. The HAY House is a flagship store for the Danish brand HAY, known for its modern, minimalist design. The building itself is designed by architect Bjarke Ingels and features clean lines and natural materials like wood and glass, creating a bright and welcoming space.

Inside, the store is organised over several floors, each showcasing a wide range of HAY’s furniture and home accessories. I found it easy to imagine how the pieces would look in different settings, as everything was thoughtfully displayed. The HAY Kitchen Market section caught my attention with its selection of stylish and functional kitchenware.

Beyond shopping, the HAY House also feels like a cultural space. It regularly hosts events and exhibitions, adding to the creative atmosphere. There's even a café where you can take a break and enjoy a coffee.

This next stage is about focusing my research on a clear narrative and context of my work. After looking at all this previous research and design development I had done up to this point, it became clear I needed to further understand these points to help structure my project.

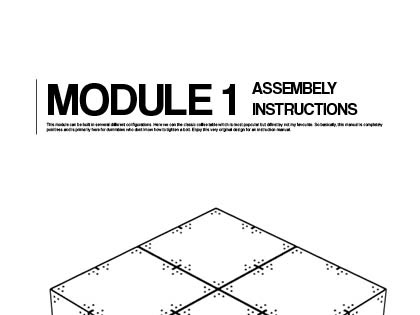

"How can simple, standardized components be designed to connect in various ways, enabling users to build furniture forms that suit their specific needs?"

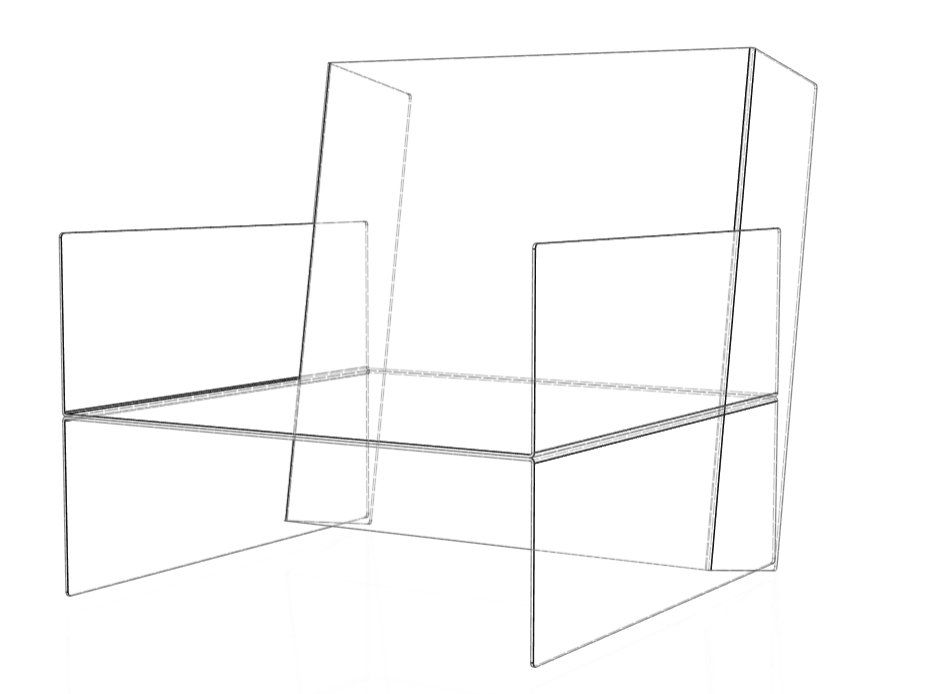

This question provided a clear narrative, allowing me to focus my research on key areas such as modularity, standardization, user customization, and the mechanics of component connections. By exploring these themes, I aim to establish a solid foundation for the BRKT project's development, ensuring that each design decision is informed by both user needs and practical assembly considerations.

Exploring the Roots of Modularity

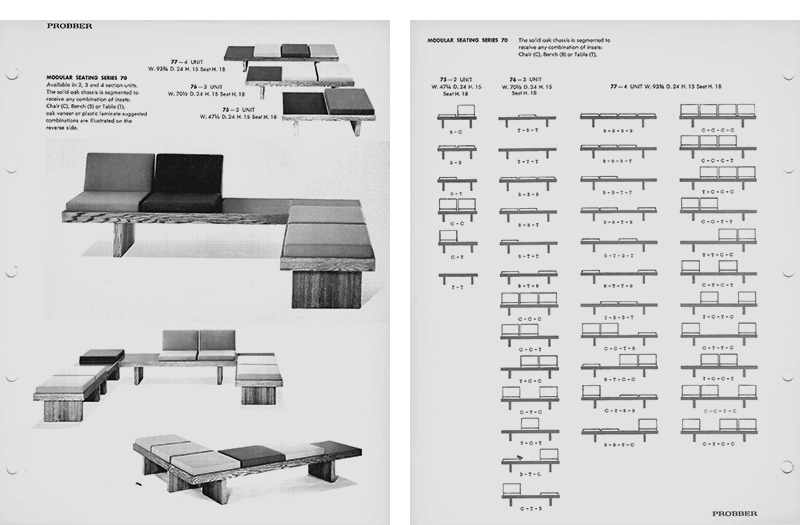

Delving into the history of modular design, I was particularly inspired by the Bauhaus movement's emphasis on functionality and simplicity. The 1940s saw the rise of modular and sectional sofas, offering affordable and expandable furniture solutions during challenging economic times. Designers like Harvey Probber pioneered modular seating, allowing users to customize their furniture arrangements.

This historical context highlighted the enduring appeal of customizable and adaptable furniture. It reinforced my belief in creating standardized components that empower users to assemble furniture tailored to their needs. Understanding these roots has been instrumental in shaping my approach to the BRKT system.

Learning from Existing Modular Systems

Analysing existing modular systems has provided valuable insights into different design philosophies. USM Haller's system is built around a patented ball joint and steel tube framework, allowing for precise and durable configurations. This approach emphasizes structural integrity and long-term adaptability.

In contrast, IKEA's modular furniture focuses on affordability and ease of assembly. Products like the EKET series utilise various connectors to enable flexible arrangements, catering to a broad consumer base. This strategy prioritizes user accessibility and rapid customisation.

Looking at these companies made me consider a few things. In previous projects I had been set on the idea of making one component fit all, this was influenced by my past research on tesselating shapes. However, after looking at brands and companies like these, it showed me 2 paths. The first following USM and creating a connecting component would have been a massive engineering challenge, as I would have looked at new, innovative methods of connection. I then looked at the second path, which was to create a collection of components to build different forms and use traditional hardware; this is following the footsteps of IKEA and many other brands.

Material Choices and Connection Methods

Given that my work primarily involves steel and aluminium, selecting appropriate connection methods is crucial. I'm exploring hardware options that facilitate easy assembly and disassembly without compromising structural integrity. Barrel nuts and bolts, for instance, offer strong joints and are commonly used in flat-pack furniture. Thumb screws and hex head bolts (operated with an Allen key) provide user-friendly alternatives that don't require specialised tools.

Conversely, self-tapping screws, which are permanent and can damage materials upon removal, are unsuitable for my objectives. My focus is on reversible connections that support the modularity and reusability of components.

Reflecting on my previous project, Edge 1.2, which emphasised material connections without hardware, I've recognised the importance of integrating mechanical fasteners to enhance functionality. In the BRKT project, incorporating suitable metal connectors aligns with my goal of creating a modular system that balances ease of use with structural reliability.

Understanding Users Needs

In exploring how to make smaller spaces more livable, I delved into the principles of Japanese micro-living. In densely populated cities like Tokyo, space is at a premium, leading to the development of ultra-compact living spaces known as "kyosho jutaku". These homes, often ranging from 50 to 300 square feet, exemplify efficient use of space without compromising functionality.

A key aspect of these designs is the use of modularity to maximize utility. For instance, furniture often serves multiple purposes, and spaces are designed to be adaptable throughout the day. The integration of built-in storage and multifunctional areas allows residents to maintain a minimalist lifestyle while having all the necessary amenities.

However, through my own design experiences, particularly when creating side tables for a previous project, I've come to understand that multifunctionality isn't always the optimal solution. While combining functions can save space, it can also lead to compromises in usability and comfort. Sometimes, a piece designed for a single, specific function can serve its purpose more effectively and enhance the overall living experience.

This realization has influenced my approach to the BRKT project. Instead of focusing solely on multifunctional pieces, I'm emphasizing the creation of standardized components that can be connected in various ways. This allows users to assemble furniture tailored to their specific needs, whether that means a single-function piece or a multifunctional configuration. By prioritizing user needs and the realities of micro-living, I'm aiming to design solutions that are both practical and adaptable.